Martin Engineering has carried out a review of Stanton Energy Center’s (SEC) conveyor system, as part of the power supplier’s innovative dust containment measures on its coal handling system.

A key Florida power supplier, Orlando Utilities Commission SEC has adopted a series of innovative dust containment measures on its coal handling system, helping the facility reduce potential hazards from fugitive material accumulations and significantly cut down the number of man-hours spent on clean-up.

By limiting dust and spillage from one of its primary conveyors, the energy provider has reduced airborne particles and virtually eliminated a potential source of trips and falls, while allowing critical manpower to be deployed on core business activities. Preventing coal dust spillage also helps minimise wear on rollers and other moving components, saving on replacement part costs and labour.

Material handling supervisor Stuart Cason said: “Typically each day after we finish filling or bunkering the silos, the whole system is cleaned.

“That includes the yard, all the conveyors, chutes, floors, impact zones and rollers. In some places, it’s a wet washdown, while in others we sweep. It’s seven days a week, every week of the year.”

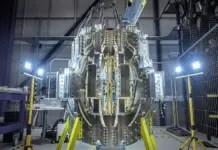

As engineers planned the upgrades, SEC contacted Martin Engineering to review the conveyor system. The team started by looking at the areas which could benefit most from new containment technology on the 36-inch conveyor, which travels at about 700 feet per minute.

SEC plant engineer Brian Moore said: “We were looking for a better method of sealing the transfer zone. We had skirt blocks and seals in place, but they were getting old, and some of them were leaking or repeatedly coming loose.”

“Coal dust is pretty abrasive, and when it got down into the impact rollers, idlers and troughers, it would pretty much eat them up,” Cason added. “We tried everything we could think of to improve the service life, but we were constantly replacing them.”

Double Apron Seal Skirting

To address the situation, Martin Engineering supplied and installed a number of upgraded components, including Double Apron Seal™ Skirting, which employs two wear surfaces on a single elastomer sealing strip installed along the bottom of the skirtboard in the loading zone. When the bottom side of the sealing strip is worn, it can be inverted to deliver a second service life.

The skirtboard sealing system is installed on the sides of the loading zone to contain dust, eliminate spillage and reduce cleanup expenses. Believed to be the first dual-sealing system of its type, it incorporates a primary seal clamped to the steel skirtboard to keep lumps on the belt and a secondary or ‘outrigger’ strip to capture any fines or dust particles that might pass beneath the primary seal.

Next, Martin Engineering technicians installed an impact cradle to better absorb the force of the falling material and protect the belt and structure. The cradle stabilises the belt’s line of travel to help prevent the escape of fugitive material.

In addition, a belt support system was added to better support the edges and eliminate sagging. To maintain precise centring in the loading zone, a belt tracking system was also installed for immediate, precise adjustment. Comprised of upper and lower components, the tracker works to reduce belt edge damage, prevent spillage and extend belt life.

A key element in the material handling system upgrade was addressing the large, under-performing dust collector.

Maintenance supervisor Jon Janis said: “We wanted to upgrade our dust collection equipment, because we knew technology had advanced since ours was installed. Even when it was functioning properly, the old unit was a high-maintenance item.”

The Martin Engineering team installed a high-efficiency insertable air cleaner with an explosion-proof motor. The automatic, self-cleaning design employs filter elements approximately one-eighth the size of conventional filter envelopes, allowing a significant reduction in the dust collector’s space requirements, so it can be installed in tight quarters.

Cason added: “The old unit had a large footprint, and it was too close to the emergency reclaim area. A smaller integrated unit gives us back that space and actually does a better job of filtering the air.”

The mesh-like material not only filters better, but lasts longer, while consuming less energy than conventional filter bags. Furthermore, the new filters allow a smaller size fan to move air through the elements, helping to reduce the overall power consumption of the collection system.

The new design features a pulse cleaning system, which uses a short burst of air sent back through the filter to dislodge accumulated material. Filter changes are a no-tool procedure from the clean side of the dust collector.

Meanwhile, Janis added: “[There is] no question that the system has paid for itself. We used to spend a lot of time making adjustments and repairs, but since the install, the system has been essentially maintenance-free.

“It doesn’t matter what kind of coal we run, or whether the coal is damp from rain or completely dry. The fines are contained.”

Cason commented: “For me, not having those clean-up and repair battles is a huge relief. And the whole area is a cleaner, safer working environment.

“We could see the improvement right away. It’s not just the savings in clean-up time, but also in preventing the idlers from wearing out prematurely.

“Manpower is at a premium right now, and every expenditure is closely scrutinised. Martin Engineering has proven its value repeatedly. They have advanced technology, but their approach is to provide application-specific solutions, not just try and sell us the latest product.”