Green hydrogen happens to be the cleanest form of hydrogen and has become a compelling aspect when it comes to the global pursuit of renewable energy as well as decarbonization. Typically taken out by way of electrolysis of water, which is powered by renewable sources such as wind and solar, this hydrogen production form looks for zero-carbon emissions, placing it right at the forefront of energy revolution strategies.

However, is the hype worth it?

The renewable energy spectrum happens to be marked by innovations that are aimed at decreasing energy waste, enhancing conversion efficiency, and, above all, cutting climate change. Theoretically, green hydrogen happens to fit perfectly into this mold. But achieving the production of green hydrogen with high efficiency as well as low cost is indeed quite a prominent challenge that researchers as well as industrial players are looking to overcome.

It is well to be noted that the biggest challenges are the dual hurdles of energy waste as well as conversion inefficiencies. Significantly, green hydrogen has often been categorized by the usage of renewable energy so as to power the reactor process by way of electrolyzers, and it is this element that can go on to garner criticism from those underscoring that this is simply cannibalizing renewable energy that could as well be used elsewhere as it was initially designed.

Efficiency in Green Hydrogen Production Vitality

Efficiency plays a very vital role when it comes to green hydrogen production. When one refers to efficiency, it is meant the energy content of hydrogen produced per unit of energy invested. The fact is that the higher the efficiency, the more hydrogen output one can get for the same input, thereby leading to enhanced utilization of renewable energy resources.

The present efficiency rates when it comes to green hydrogen production happen to be still low as compared to conventional fossil fuel-based methods. This is majorly because of energy losses in the electrolysis process as well as losses in power conditioning as well as transmission. Overcoming these issues can go on to help make green hydrogen more competitive while at the same time accelerating the shift toward a completely renewable, decarbonized energy system.

Lessening Renewable Power Requirements: A Key Component of Green Hydrogen Production

While enhancing efficiency is indeed crucial, green hydrogen production must also be attained sans taxing the renewable power supply, as, after all, it is not just splitting water and calling it green. The intensity of energy in the electrolysis process goes on to directly affect the cost and sustainability of green hydrogen production. A lesser renewable power need means less strain when it comes to renewable energy resources, as well as an overall dip in the cost of hydrogen.

But achieving high efficiency as well as low renewable power demand in green hydrogen production is not just a straightforward task.

The electrolysis process goes on to require 45-65 kilowatt-hours of renewable energy per kilogram of hydrogen that is produced. Hence, a 500-ton-per-day industrial hydrogen project could go on to require more than one gigawatt of renewable power. It is worth noting that the key to creating green hydrogen efficiently by way of using low renewable power demand lies within technological innovations as well as process optimizations like advanced electrolyzer designs and also novel catalyst materials.

The convergence when it comes to high efficiency and low renewable power: a path to decarbonization

When one successfully goes on to blend high efficiency and low renewable power demand, or for that matter, no renewable power for green hydrogen production, one can embark on a more feasible pathway when it comes to decarbonization, both by way of a business sustainability perspective and an environmental element. Green hydrogen can then go on to serve as a viable means so as to store as well as distribute renewable energy, get various sectors like transportation, chemicals, as well as steel to transform, and thereby, ultimately, push the worldwide shift to a zero-emission society.

A world which is powered by efficient, zero-electricity green hydrogen would go on to have a significantly lesser carbon footprint while at the same time potentially elevating its resilience. When one goes on to remove the need for renewable energy sources, one eliminates all the barriers that are holding back the anywhere as well as anytime production when it comes to pure and clean hydrogen.

Innovations as well as Challenges in Green Hydrogen Production: The Road Ahead

It is worth noting that the future when it comes to green hydrogen goes on to depend on its ability to enhance efficiency and reduce energy consumption in its production. Although various companies have attempted to evolve the existing systems as well as processes, the journey ahead should be viewed as a revolution rather than an evolution.

At Utility, it is believed that the creation of completely novel and ground-up solutions is going to be the way forward. Continued research, technological advancements, as well as supportive policy frameworks happen to be critical when it comes to propelling green hydrogen to its exact place at the heart of the energy shift.

The investment when it comes to green hydrogen technologies is not just an economic endeavor; it is an investment in the future of the planet. By pushing forward high efficiency as well as low-to-no-renewable power production of green hydrogen, one can catch a unique opportunity in order to reshape the world’s energy spectrum and make a prominent contribution so as to mitigate climate change.

Build-ups in Green Hydrogen Production

Traditionally, the major factor when it comes to determining a hydrogen color was the kind of energy that was used. Green hydrogen, having been coming from renewable electricity, has gone on to create a major hurdle to making this class of hydrogen one of the mainstream energy sources.

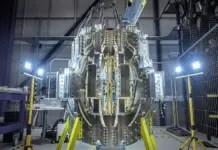

With innovations going ahead and eliminating electricity from the reactor process as well as making the distinctions of rainbow hydrogen moot like utility Global’s eXERO technology platform, for instance, the focus can now make a move from a color title to the actual carbon intensity of the hydrogen that’s produced.

Advancements in terms of catalyst materials happen to be aiming to lessen the energy needs of the electrolysis process. For instance, catalysts based on nanoparticles have gone on to showcase elevated activity and durability, helping electrolysis to occur due to lower renewable power demand. These innovations happen to be moving the system closer to the objective of efficient as well as low-renewable energy green hydrogen production.

Policy Implications and the Industry Role

Interestingly, the sector’s role in advancing green hydrogen can sure not be understated. As the technology goes on to mature, it will need major investment as well as adoption from the chemical and clean energy verticals. Moreover, supportive policy steps happen to be critical so as to help with this shift. Incentives when it comes to renewable energy use, subsidies for green hydrogen projects, as well as carbon pricing can all go on to encourage the creation and use of green hydrogen.

The road to efficient, low-renewable energy, green hydrogen also needs combined international cooperation. The shared benefits in terms of green hydrogen, reducing climate change, energy security, and industrial development happen to make it a common cause for all countries. By way of global partnerships as well as knowledge sharing, one can speed up the growth of green hydrogen technologies.

The Green Hydrogen Production Imperatives

The potential when it comes to green hydrogen as a major player in decarbonization along with renewable energy development is massive. Although attaining this potential relies on the combined ability to generate green hydrogen by way of both high efficiency and low-to-no renewable power. By taking into account this challenge, one is not just tackling a technical problem but, at the same time, taking a major step in the journey toward a sustainable as well as decarbonized future.