EDF Energy Renewables places order for five V164-8.0 MW turbines for the Blyth Offshore wind farm in the UK.

The project will test several ground-breaking technologies. The turbines will utilise a power mode to increase performance.

MHI Vestas Offshore Wind has received an order from EDF Energy Renewables for five V164-8.0 MW turbines in the UK. The 41.5 MW Blyth Offshore Demonstrator Project will test several innovative technologies including a 66 kV electrical infrastructure, and gravity base foundations.

The V164-8.0 MW turbines – rated with a capacity of 8 MW – have been optimised for the project, utilising a power mode to be able to deliver a maximum output of 8.3 MW, further increasing the value for the customer.

“We are delighted to have received an order from EDF Energy Renewables for the Blyth Offshore Project,” said Jens Tommerup, CEO of MHI Vestas Offshore Wind. “Blyth will be the first offshore project which MHI Vestas and EDF Energy Renewables will install together, and we look forward to partnering on an innovative project where the latest technologies will be tested.”

The order includes a 15-year full scope service contract with an availability guarantee, ensuring optimised performance of the wind power plant with maximum power output.

Innovative technology

The Blyth Offshore Project will be the first to feature 66 kV electrical infrastructure. The V164-8.0 MW turbines feature new transformers and switchgears to enable connection to the 66 kV grid. Use of the 66 kV system allows approximately double the amount of wind turbines to be connected on one equivalent array cable string compared to the existing 33 kV system, resulting in a reduction of the electrical infrastructure per megawatt installed and thus, a significant cost saving for producing offshore wind power.

Furthermore, the project will utilise gravity base foundations – the first time this specific type of foundation will be used for an offshore wind power plant. The hybrid foundation combines the widely used steel reinforced concrete foundation, with the well-known steel monopile, allowing the foundation to be installed in deeper waters (45 m) while eliminating noise from pile hammering during installation.

About the Blyth Offshore Project

- • Owned by EDF Energies Nouvelles group and operated by EDF Energy Renewables, a 50-50 UK joint venture between EDF Energies Nouvelles and EDF Energy

- • Five V164-8.0 MW turbines, with a power output of 8.3 MW

- • Located 5,7 km off the coast of Blyth, north of Newcastle, UK

- • 15-year full scope service contract with availability guarantee

- • Installation expected in 2017

- • First offshore wind power project to utilise 66kV electrical infrastructure and hybrid gravity-monopile foundations

- • 45 m water depth

- • Pre-assembly for the project will take place in Esbjerg, Denmark

- • Commissioning and maintenance harbour will be Blyth, UK

For more information, please contact:

Matt Whitby, Press Officer

MHI Vestas Offshore Wind

Tel: +45 2250 7131

Mail: matke@mhivestasoffshore.com

About MHI Vestas Offshore Wind

MHI Vestas Offshore Wind is a joint venture between Vestas Wind Systems A/S 50% and Mitsubishi Heavy Industries (MHI) 50%. The company’s sole focus is to design, manufacture, install and service wind turbines for the offshore wind industry. The company aims to drive down the cost of energy from offshore wind parks by driving capital and operating savings, and increasing output of wind turbines by bringing the best technology to the market. The company is founded on collaboration, and creating powerful partnerships with key stakeholders is the cornerstone of its business model.

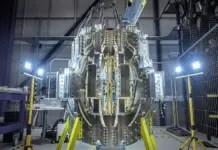

About the V164-8.0 MW

- • 8 MW rated power, with an optimal rotor to generator ratio

- • 80 m blades, the equivalent of nine double decker London buses

- • Each blade weighs 35 tonnes

- • Swept area of 21,124 m2 – larger than the London Eye

- • The nacelle is 20 m long, 8 m wide and 8 m high, weighing approximately 390 tonnes

- • Approximate hub height of 105 m (Østerild prototype 140 m)

- • Approximate tip height of 187 m (Østerild prototype 220 m)

- • Reduces operational and maintenance costs by enabling customers to run fewer, larger turbines

- • World record production by a single wind turbine of 192 MWh during 24-hour period (October 2014)